We are proud to distribute ITW's Plexus brand of structural adhesives. Plexus provides a range of advanced structural adhesives that improve manufacturing and assembly techniques and processes. The wide ranger of advanced adhesive products are suitable for bonding a vast majority of composites, thermoplastics, metals and dissimilar substrates that result in durable bonds capable of withstanding the harshest climatic conditions with minimal or no surface preparation.

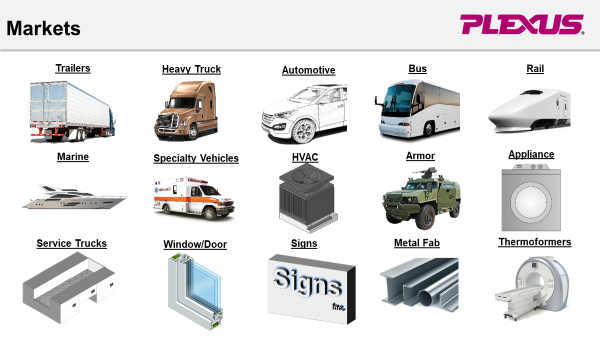

The toughness and durability of Plexus Adhesives help contribute to long lasting assemblies and are trusted and spec’d in for many different markets including trailers, heavy truck, automotive, bus, rail, marine, specialty vehicles, HVAC, armored car, household appliance, service trucks, windows and doors, signs, metal fabrication, thermoformers, and more.

Manufacturers turn to Plexus adhesives to help solve key problems in manufacturing and assembly:

Save Time

Plexus® adhesives are primer-less, which require little to no surface preparation. They can be dispensed quickly and offer fast unclamp times. Often Plexus® is used to eliminate rework from welds heat distortion or eliminate secondary sealing steps.

Improve Durability

Distributing stress across bond lines and not concentrating to point loads is a big design advantage. This combined with Plexus® adhesives excellent fatigue resistance and high toughness often leads to longer lasting assemblies.

Lower Cost to Assemble

Plexus® adhesives is one of the most cost effective joining methods when you look at (strength X surface area) per $. Plexus has been used to drastically reduce labor costs and speed up assembly times in multiple industries.

Reduce Leaks

Join and seal in one step with Plexus adhesives. No holes are required. Stress is distributed and assemblies are less prone to stress cracking. All this leads to a reduction in leak potential.

Design Freedom

Plexus adhesives are primer-less to metal, composites and most thermoplastics.

Clean Aesthetics

no holes or visible welds are required.

Bonding applications for Plexus in transportation are numerous.

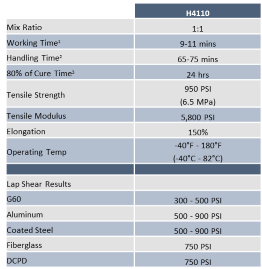

Plexus® H4110 2K Hybrid Adhesive

Features and Benefits

Elastic and Primerless Adhesion

Bonds composites and metals and allows for joint movement

No Print Through

Ultra low exotherm, shrink and high elongation leads to no print through

Eliminate Dependence on Moisture

1:1 mix ratio that cures without atmospheric moisture

Easy to Incorporate

Paintable, non-flammable and UV resistance

Fill out our form and an Austin Hardware® solutions consultant will contact you!

"Since my company entered into a vendor managed inventory program with Austin, our service levels and in-stock position on our parts have never been better. We consolidated 23 suppliers down to one, Austin.

Now we only have one invoice to review, one shipment to check in and we are in stock 99% of the time! Austin has one of the best customer service teams we work with, I would recommend this program to anyone who needs to take control of their inventory and be sure to have the parts you need on the shelves!"

Gary from Ohio

"I wanted to send along some great news. We have experienced a few problems with shipping over the years, but the solutions that you put in place over the last few weeks have been very positive. On another note, Tom and Emma, the Vendor Managed Inventory team that I have been working with, have done a great job responding to concerns and questions in a timely fashion. That fact is another reason our VMI program is successful and getting stronger every day. Our overall numbers continue to increase and we are looking forward to the growth in 2017."

Shawn from Texas