Austin Hardware® is excited to partner with Prairie Rivet, a leading supplier of semi-tubular and solid metal rivets since 1957.

Solid Rivets

Solid rivets have a history of being among the simplest and most reliable types of permanent fasteners. They are commonly used in aircraft and structural appliances like bridges and buildings where reliability and safety are essential.

Why use Solid Rivets?

- High-speed assembly

- Ease of joint inspection

- Easily adapted for automation

- High shear strength values

- Inexpensive alternative to threaded fasteners

- Little to no scrap is produced during the manufacturing process

- A permanent fastener that cannot be removed unless one end of the rivet is sheared off

Solid rivet LINE CARD for available styles, sizes, and materials.

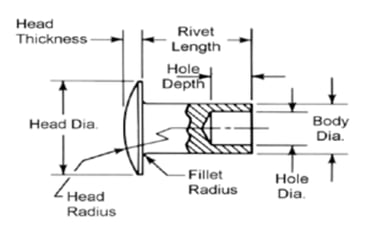

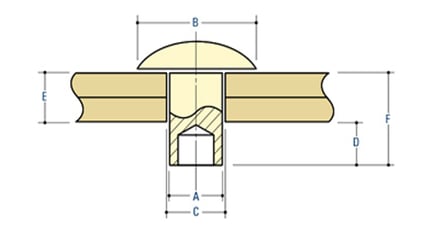

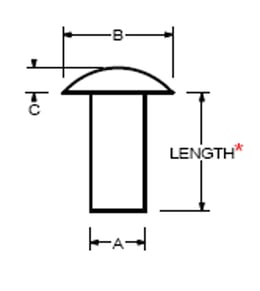

Similar to the semi-tubular rivet, the measurements of a solid rivet include A. Shank Width, B. Head Diameter, C. Head Thickness / Head Radius and D. Shank Length. As fasteners go, solid rivets have been used for many millennia and are some of the most reliable and simplest fasteners to this day. The solid rivet consists of a solid shank or shaft with a head on one end. Solid rivets may be the most widely-preferred style of rivet for permanent and secure fastening.

Similar to the semi-tubular rivet, the measurements of a solid rivet include A. Shank Width, B. Head Diameter, C. Head Thickness / Head Radius and D. Shank Length. As fasteners go, solid rivets have been used for many millennia and are some of the most reliable and simplest fasteners to this day. The solid rivet consists of a solid shank or shaft with a head on one end. Solid rivets may be the most widely-preferred style of rivet for permanent and secure fastening.

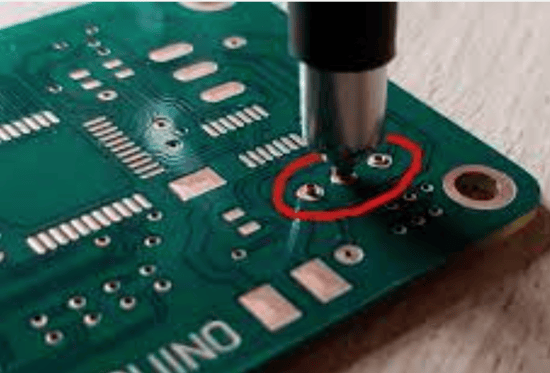

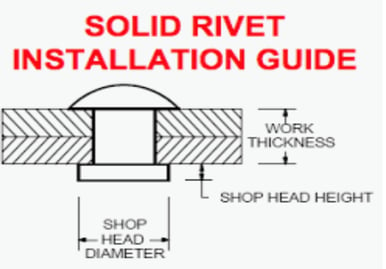

Solid Rivet Installation

During installation, pressure is applied to both the head and the end of the shank (shown as Shop Head Diameter); during compression, the shank will take on a similar shape as the head and allows for a firm and permanent connection between two materials or components. Perhaps the most widely-used style of rivet, solid rivets are utilized in applications where reliability and permanent securing are important.

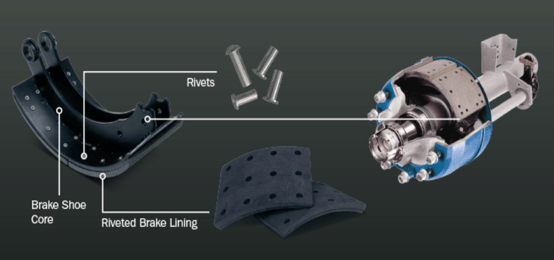

Solid Rivet Applications

Trailers

Boats

Aircraft

Clothing

Locomotive

Cookware

Quality Assurance

Quality assurance is something Prairie Rivet has been committed to since day one. They have taken the extra step to formalize their existing process through ISO certification. The ISO 9000 family is the manufacturing industry-trusted standard for quality.

From the time the raw materials are received at Prairie Rivet to the moment the end products are shipped out, they are implementing their quality assurance program to ensure customers receive only the highest-quality parts.

Prairie Rivet’s 6-Step Quality Assurance Process:

- As raw materials are received experienced operators conduct a visual inspection.

- As the raw materials are pulled for order processing, they receive an additional visual and measurement inspection.

- Once an order is ready to process, each machine required to produce that order is calibrated precisely for that order’s specifications prior to starting production.

- Throughout production/order processing, the Prairie Rivet team of machine operators meticulously measure and visually inspect small batches, up to five times an hour, to maintain a consistent quality product during production.

- If an issue is identified, the team quickly assesses, rates, documents, and then addresses the issue to eliminate errors or omissions in the order and minimize downline time.

- Once the order is complete, it is prepared for shipping by hand. It receives a final visual inspection by the shipping and receiving team before the final boxing and shipping of the order.