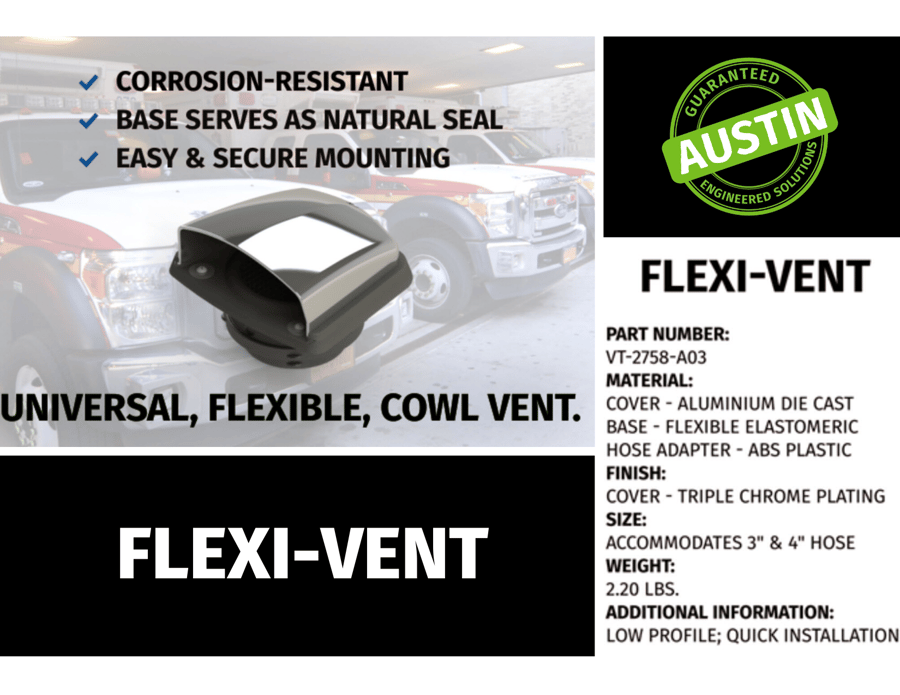

FLEXI-VENT

THE FLEXIBLE MOUNTING COWL VENT

The universal, flexible, cowl vent is another Austin Engineered Guaranteed Solution for your business. Easy to install and corrosion resistant, the Flexi-Vent is designed for use in many different industries and applications.

Easy install, corrosion resistant, these are pretty much the standard qualifications for a cowl vent. Pretty basic, right?! So how did the Flexi-Vent come to life? What sets it apart from the other cowl vents on the market?

Click here to purchase the Flexi-Vent today!

How and Why The Flexi-Vent was Engineered

Market Trends

We can all see how the automotive industry is stepping away from the “box” look. Today, it is hard to find a newer vehicle that isn’t created with convoluted shapes and aerodynamic contours. This styling trend is popular today among the vehicles used in the Emergency Vehicle market such as the Transit Connect (Ford) Pro Master (Dodge) and Sprinter (Mercedes Benz) models.

Customer Feedback – Help! Emergency!

As vehicle design trends advanced and cowl vent innovation lagged, the rigid base of the vents caused the Emergency Vehicle market to see failures and cracking over-time. The design flaw created the need for manufactures to replace these vents and led to painful and costly rework. While learning more about this issue with our customer, they asked “Why can’t the base just be flexible? If the base was flexible, the cracking scenario would be eliminated AND we could install the vents on any shaped surface”.

That’s when the light came on and our engineering team quickly started pursuing the opportunity to provide our partner a new innovative solution that proactively resolved their existing issues and made additional product improvements.

Custom Engineering Solutions

After a comprehensive study we set our sights on designing an improved cowl vent that would eliminate 3 significant problems. As a result of our efforts, we are able to offer a low-profile, corrosion resistant vent, that also eliminates other frustrations customers are experiencing today.

- The Austin Engineering team designed a rubber base allowing the vent to flex and mount to the contours of the automotive vehicles used in the Emergency Vehicle industry. This prevented the vents from cracking, provided a natural water seal and allowed the manufacture to mount our Flexi-Vent in the optimal position on their vehicles.

- While we were at it, we designed a mesh filter into the base, eliminating an additional component for the installer to manage.

- Last, but not least, the Austin team designed a hose adapter, allowing for not one, but two hose sizes commonly used with cowl vents. Accommodating both a 3” hose and a 4” with no additional parts necessary.

If you would like more information regarding our Engineering capabilities and how we can partner with you and your business, please contact us at contactus@austinhardware.com and view the video below for a quick view of our engineering capabilities.

For more information on Austin Hardware's products and services, please complete the form below: