Full T304 Stainless Steel Lockbolt System

G-Grip™ by Goebel® is the new and improved standard in the market for applications where a wide grip range is needed, and a consistent flush pin-break to the collar is favorable. The extensive grip range and various sizes can replace up to 14 sizes of the classic 6-groove locking fastener system.

G-Grip™ by Goebel® is the new and improved standard in the market for applications where a wide grip range is needed, and a consistent flush pin-break to the collar is favorable. The extensive grip range and various sizes can replace up to 14 sizes of the classic 6-groove locking fastener system.

Features and Benefits

Multi-Grip - The G-Grip™ extensive grip range and various sizes can replace up to 14 sizes of the classic 6-groove locking fastener system. The unparalleled advantage of using a multi-grip part is that it improves cost efficiency, lowers inventory costs, and increases job site performance by simplifying the installation process.

High Corrosion Resistance - The G-Grip™ pin and collar parts are made of polished T304 stainless steel and can be coated with chrome on nickel plating upon special request. These newly developed and patented parts are only available from Goebel and promote a highly corrosion-resistant solution. Stainless steel is a proven solution for industrial applications, especially in harsh environments. Using stainless steel parts guarantees the application has lower maintenance costs, increases structural integrity, and keeps investments profitable.

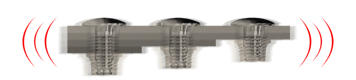

Vibration Resistance - The G-Grip™ has been tested and developed to be vibration-resistant in all applications. The collar is swagged onto the pin during installation and locked in place via the grooves. Once installed, the locking feature guarantees consistent clamping forces, shearing, and tensile values. Once these parts are installed, you can be confident that the application is secure.

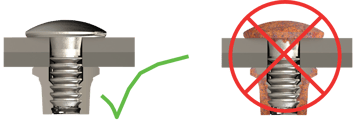

Flush Breaking Pin - Stainless steel is ductile, and efforts to guarantee consistent flush breaking have been challenging. To ensure consistency, Goebel developed a patented design that has proven to break flush every time. Various design factors guarantee this and thus create a smooth, safe, and simple installation during every use.

Efficient Installation Process - Goebel offers a comprehensive range of installation tools for their patented G-Grip™ T304 stainless steel lockbolt system. They range from hand tools, cordless battery tools, and pneumatic air tools. Choosing the best tool for your application is simple, depending on the frequency of use. Goebel's tools are user-intuitive, and parts are easily identified on the job site. G-Grip™ lockbolts are installed within seconds and, depending on the tool used can be set up to 1,200 pieces per hour. The operator can quickly identify a solid flush installation and continue working efficiently.

Goebel Tools Feature

-

- Ergonomic Design

- Safe and Quiet Setting Process

- Consistent Installation Setting Each Time

Reduced Inventory Needed of Standard Parts - As previously noted, the G-Grip™ allows you to reduce the number of SKUs you must carry. This helps you create a cost-efficient inventory system, vital in today's manufacturing setting.

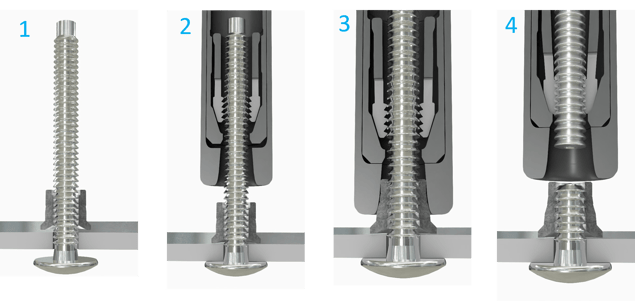

Installation Sequence

-

The G-Grip™ pin is inserted in the prepared hole from one side, whereas the collar is placed on top of the pin’s end and is pushed down until it reaches the working piece.

-

The pin is inserted in the nosepiece of the installation tool. The nosepiece goes downwards along the pin until it reaches the collar.

-

The next step is pushing the button of the installation tool; the swaging process of the collar starts immediately. In the meantime, the jaws inside the mouthpiece started to pull the pin until it broke off. The setting process is done now.

-

The result is a flush broken pin and a tight-fitting collar. The combination of the pin and collar results in a high permanent clamping force, and they are mechanically locked.

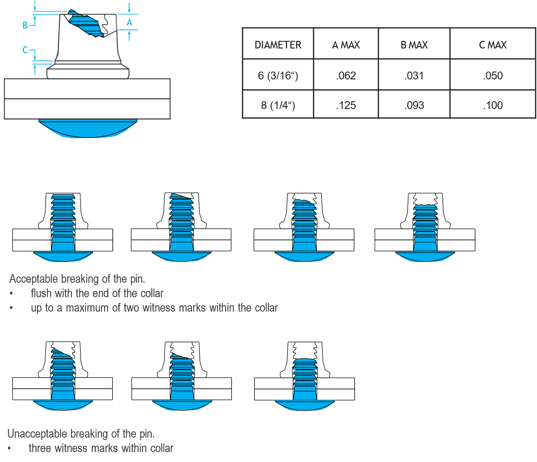

Inspection Data

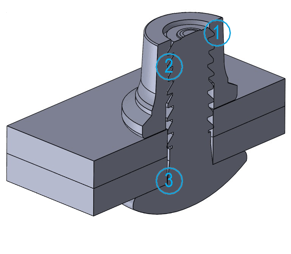

- The G-Grip™ design guarantees flush-breaking stainless steel pins. These pins lock with the custom stainless steel collar. The G-Grip™ can be used for various grip ranges and, therefore, reduce inventory levels.

- The pin grooves are being filled up by collar material during the swaging process. This locks the working piece and results in guaranteed vibration resistance. With increased customer satisfaction and reduced warranty claims, this part is an excellent solution for any application.

- The G-Grip™ lockbolt system has unique features that result in high yield values, consistent clamp loads, and gaps filled out by the collar swaging process.

For specific G-Grip™ sizes and ordering details, please download our G-Grip™ Ordering Guide.

For more information on Austin Hardware's products and services, please complete the form below:

For more information on Austin Hardware's products and services, please complete the form below: